Industrial IoT Solutions for Smarter Equipment

Unlock machine intelligence with real-time data. See how manufacturing leaders turn connected machinery and teams into a competitive edge.

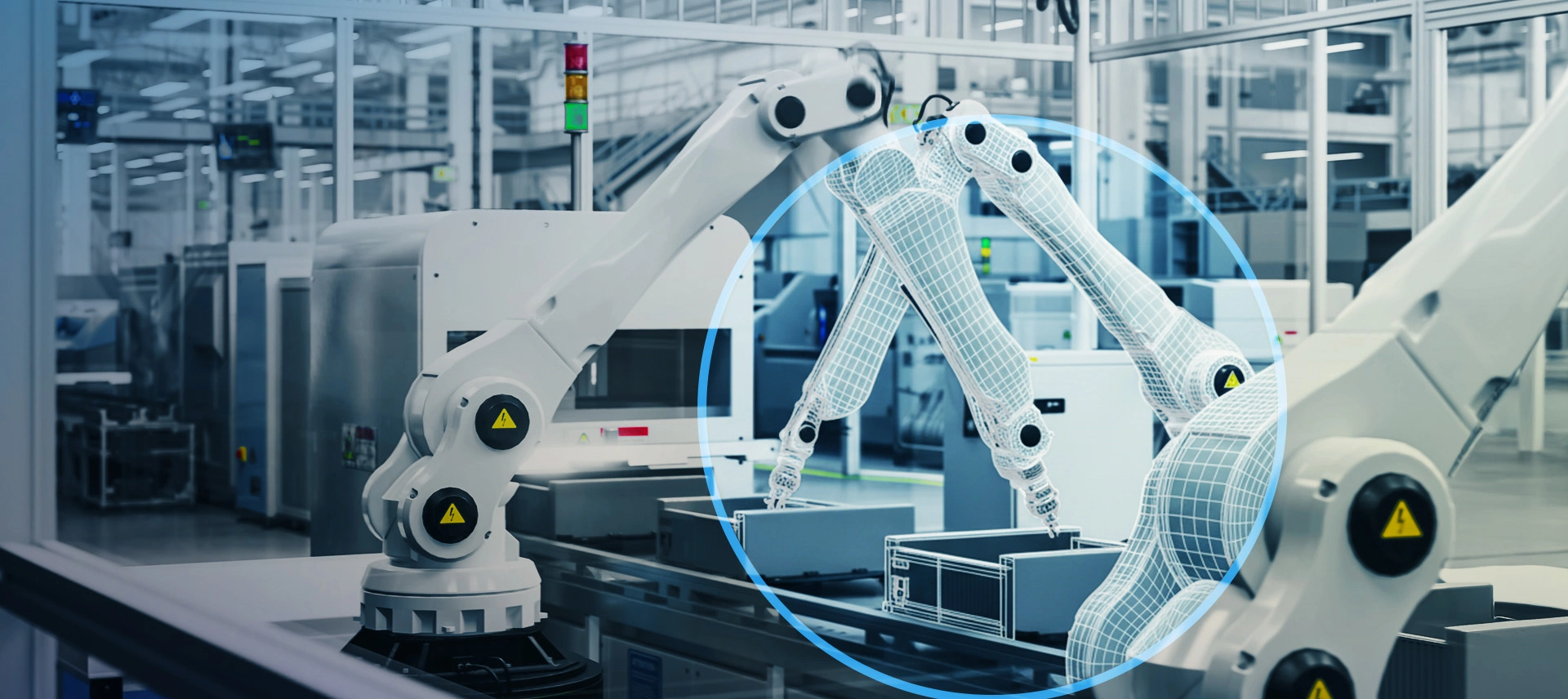

A New Era of Intelligent, Connected Machines

Smart equipment performs at its best when every system, component and team is connected. Advanced Industrial Internet of Things (IIoT) solutions make that possible through embedded software in machinery, cutting-edge sensors and real-time operational intelligence. When data flows seamlessly through connected machinery, decisions are made faster, processes are optimized, waste is reduced and equipment becomes more adaptable from the outset.

With the global IIoT market projected to reach USD286.3 billion by 2029¹, the shift toward intelligent, connected, software-defined machines will put you in the lead. Are you ready for it?

Powering the Smart, Connected Systems in Manufacturing

Dassault Systèmes’ 3DEXPERIENCE® platform creates a unified environment for manufacturers to design, build and run smarter equipment. By combining virtual twins with IIoT data and software-driven automation, the platform enables every stakeholder across multidisciplinary teams — such as design, production and service — to work on the same model, aligning across disciplines and making decisions faster, powered by real-time data.

The digital transformation redefines equipment intelligence, enhancing how engineers work and discovering new methods to collaborate, innovate, learn and produce.

Key Capabilities of IIoT Solutions and the 3DEXPERIENCE Platform

- Predictive Maintenance

- Remote Monitoring and Control

- Performance Optimization

- Digital Continuity

Predictive Maintenance

Unplanned downtime costs industrial manufacturers almost USD50 billion a year². No manufacturer could afford that cost today.

Conventional scheduled maintenance checks are no longer sufficient to confirm asset reliability in today’s fast-paced, complex manufacturing environment. Predictive maintenance software powered by virtual twins utilizes real-time data, including vibration, temperature and energy consumption, to simulate what-if scenarios. This helps identify potential issues, detect even the smallest changes and accurately predict asset failure before it occurs.

The impact? Fewer unplanned downtimes, reduced maintenance-related risks and significantly lower cost. In today’s data-driven manufacturing, predictive maintenance becomes key to overall operational efficiency, strengthening business resilience.

Remote Monitoring and Control

Imagine having complete visibility for every issue, big or small — at the remotest locations, around the world — without actually being physically present.

Cloud-based machine control gives engineers 24/7 access and control over their equipment’s system health, error logs and operational status, enabling them to diagnose, configure and act immediately to deliver data-driven support. This capability not only saves costs and eliminates downtime but also improves safety and highlights errant environmental emissions.

Remote monitoring optimizes performance, driving customer satisfaction and enabling new business models, such as Equipment as a Service (EaaS), to expand after-sales revenue. This is a value-added differentiator that enhances competitiveness and unlocks new revenue streams.

Performance Optimization

Smart, connected machines need continuous data for iteration and optimization. Through a single source of truth, iteration becomes instant, empowering manufacturers to:

- Refine designs and innovate quickly

Simulating real-world use, comparing the results with actual field data and optimizing design with virtual twins can help refine future-ready machines that are smarter, stronger and more durable. - Boost operational efficiency

Integrating data from end to end for virtual commissioning provides real-time insights that help identify bottlenecks, anomalies and inefficiencies, allowing for immediate adjustments to reduce energy consumption and increase throughput. One framework found a general overall gain of an 18% reduction in energy consumption, a 22% decrease in machine downtime and a 15% improvement in resource utilization³.

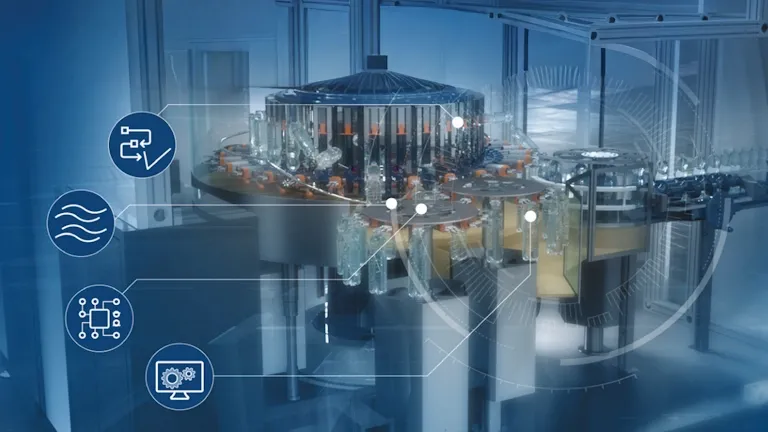

Digital Continuity

Digital continuity, the seamless and integrated flow of data across the product lifecycle and business operations, creates a single source of truth to deliver higher precision, faster delivery and better product performance.

Every essential part of the shop floor, from machines to multidisciplinary systems, connects to deliver value. For example:

- The virtual twin enables high-fidelity virtual prototyping to take place, offering design done right the first time

- Physical machines are tested virtually and optimized to withstand real-world stresses and deliver significant results

- Cross-discipline engineering collaboration, including designers, engineers, service technicians and production and line managers, reduces late-stage rework and ensures that every decision is built on updated data and real-time insights

The Factory of the Future Is Here

In an increasingly challenging industrial equipment landscape, why wait for disruption when you can act now? By harnessing IIoT solutions for connected devices powered by the 3DEXPERIENCE platform, manufacturers can predict and take proactive measures to overcome industry challenges, lead the market and set new performance standards — one defined by smarter machines, leaner operations and more adaptable business models.

The 3DEXPERIENCE platform offered a holistic solution, with diverse modules covering all aspects of our digital scenarios. This is very appealing to us.

Unlock the Benefits of Platform-Driven Connected Machines

Your Industrial IoT Solutions Questions Answered

Discover the Future of Smart Manufacturing With IIoT Solutions

The Value of Digital Transformation

Discover how digitalization enables manufacturers to listen better, respond faster and innovate smarter.

3DEXPERIENCE Platform for Intelligent Connected Systems

Imagine, engineer and experience the next generation of smart connected machines that catalyze growth and potential.

¹Source: Markets and Markets

²Source: Forbes

³Source: Research Gate